OUR SOLUTIONS FOR YOUR LEAK TESTING (NDT LT)

Are you seeking a reliable, quick, and lasting solution to verify the integrity of your welded joints? Flying Vision has developed an innovative range of vacuum box for leak testing, meeting most of the requirements for bubble leak testing using a vacuum chamber.

Can’t find the right solution for your setup ? Seeking vacuum boxes for sale ? Wondering about vacuum box testing equipment price ? Do not hesitate to contact us for custom adaptations of our vacuum box systems or bespoke development.

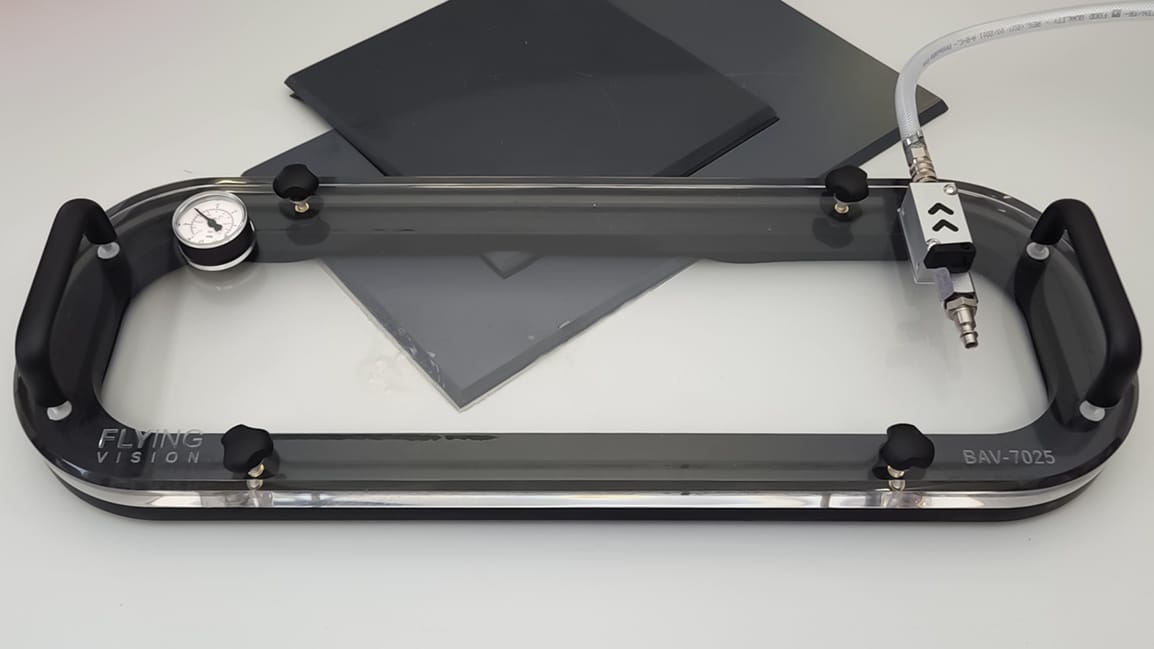

Our vacuum box

BAV-7025

Flat Vacuum Box BAV-7025

Our BAV-7025 vacuum box for flat surfaces provides an ideal solution for inspecting large areas with astonishing reliability and speed. It’s the perfect choice for leak testing welds on flat sheet metal, large-radius cylinders, waterproofing membranes for roof terraces, flat roofs, and more…

BAV-4025

Flat Vacuum Box BAV-4025

Our BAV-4025 vacuum box for flat surfaces provides an ideal solution for inspecting large areas with astonishing reliability and speed. It’s the perfect choice for leak testing welds on flat sheet metal, large-radius cylinders, waterproofing membranes for roof terraces, flat roofs, and more…

BAV-4025IA

Internal right angle vacuum Box BAV-4025IA

Our BAV-4025IA vacuum box for internal right angles provides an ideal solution for leak testing 90° internal corner welds, such as inside storage tanks to check the shell-to-bottom joint, and also in all types of tanks and containers…

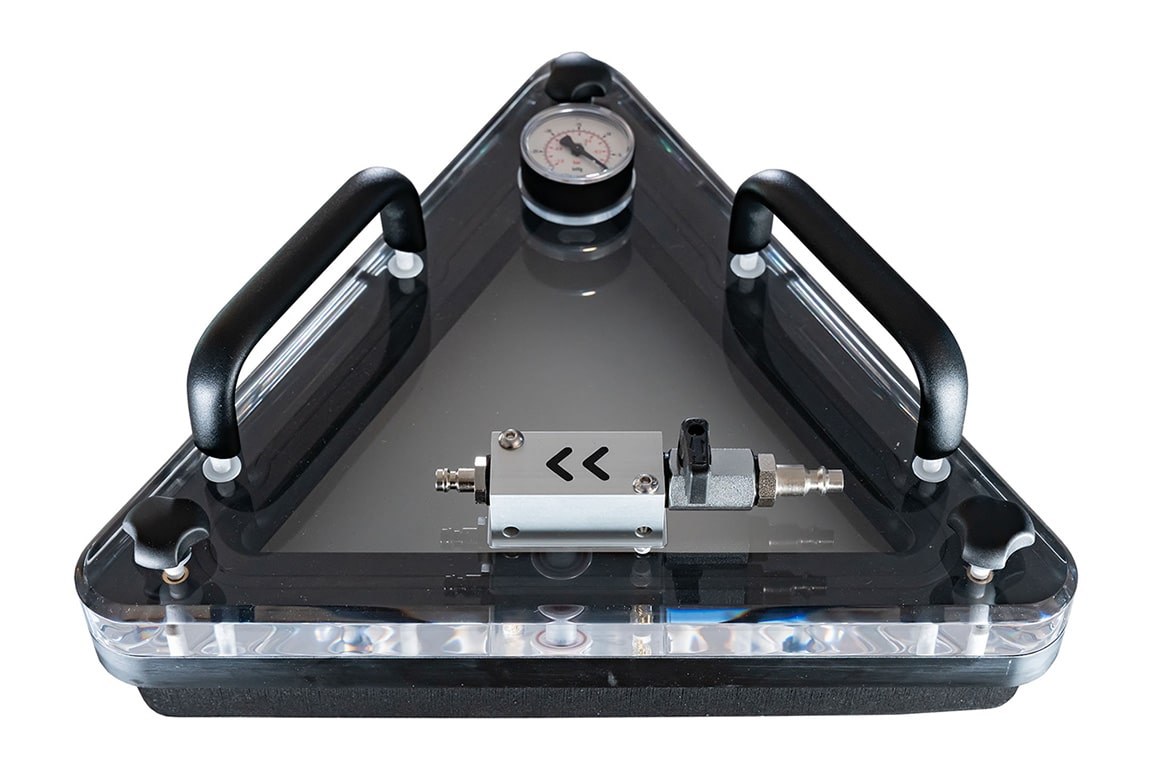

BAV-40IC

Corner vacuum Box BAV-40IC

Our BAV-40IC vacuum box for internal right-angle corners offers an ideal solution for leak testing 90° internal corner welds, for example, inside mechanically welded assemblies, tanks, and containers…

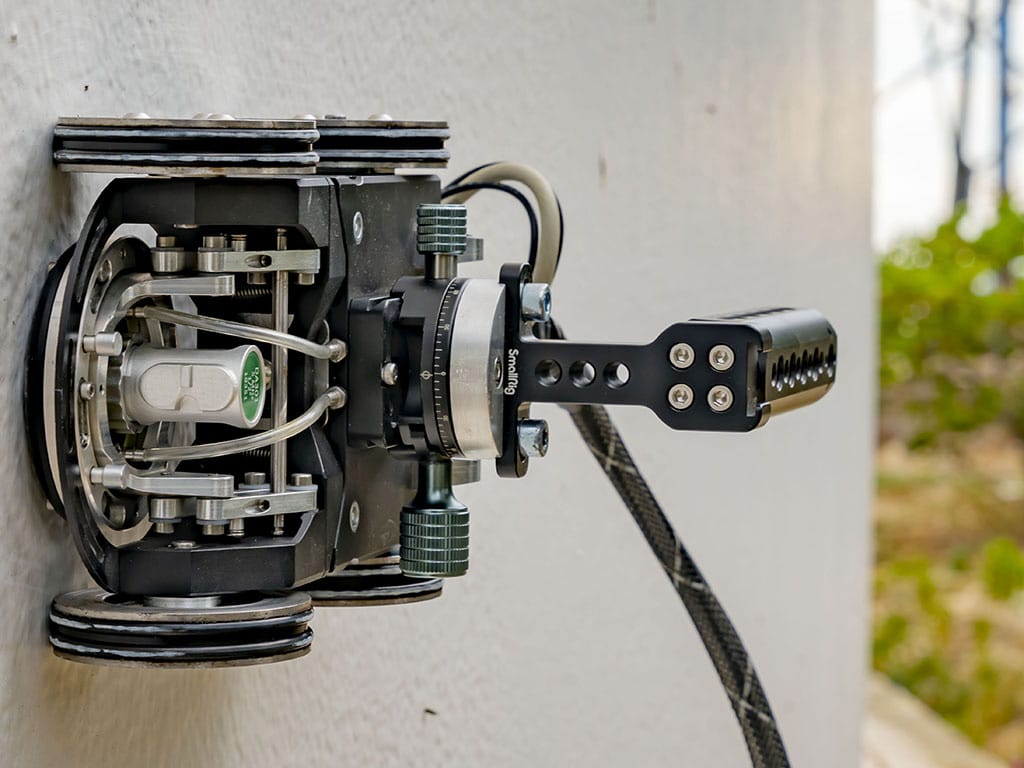

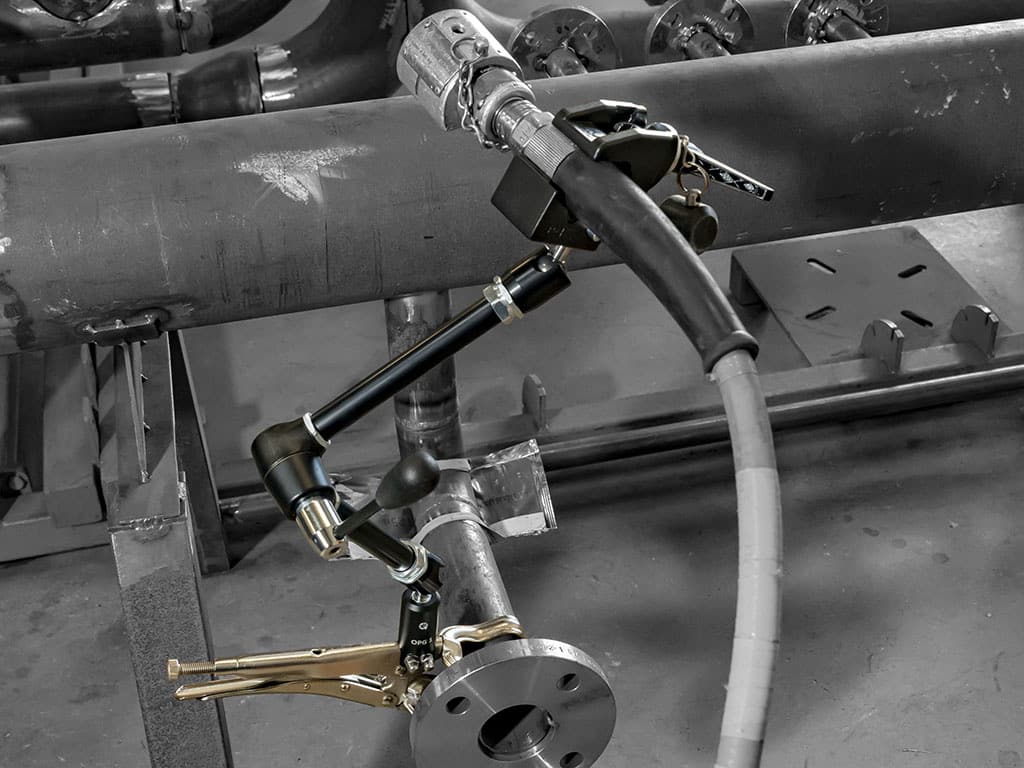

Our vacuum box accessories

Vacuum box leak testing

Operating principle

Vacuum box testing is a non-destructive testing (NDT) method used to check the seal integrity of welded joints. This process utilizes a vacuum box, often made of Plexiglas, in conjunction with a vacuum system to create a pressure differential. A reactive agent, which generates bubbles, is applied to the surface under test.

Purpose of the bubble leak test

The main goal of this bubble leak testing method or vacuum box inspection is to identify leaks in systems that cannot be conventionally pressurized. In the event of a leak, the reactive agent creates bubbles, providing a visual indication of the leak.

Therefore, it is essential to maintain a clear reading of indications that the distance between the vacuum box’s window and the inspected surface be at least 1 to 2 cm.

Areas of application

- Vacuum box test for tanks / Storage tanks (vacuum box testing tank bottom or shell)

- Ship hulls

- Overlap, butt welds (vacuum box weld testing equipment)

- Roofing waterproofing sheets and membranes for flat or terrace roofs

- Any other surfaces (metallic or not) where a pressure gradient can be applied

General design of our industrial vacuum box

To address the issues of equipment maintainability (maintenance), versatility, and to ensure good readability of indications (height of the viewing window), we have developed a line of vacuum box with a completely innovative two-part design:

- The main body composed of handling grips, a pressure gauge, and an integrated hybrid vacuum system for optimal compactness.

- The base composed of foam tailored to the configuration of your inspection surface. This base primarily ensures a sufficient viewing window height for reliable inspections and allows for equipment longevity, as the foam base becomes an easily replaceable consumable.

Control Configurations

Our range of vacuum box testing equipment covers a wide array of inspection configurations:

- Flat welds, butt, overlap, fillet, with our flat-base vacuum box ndt (types BAV-7025 or BAV-4025)

- Internal right-angle welds with our internal corner vacuum box (types BAV-7025IA or BAV-4025IA)

- Internal corner welds with our triangular corner ndt vacuum box (type BAV-40IC)

It should be noted that the bases of our flat and internal right-angle vacuum box are interchangeable, allowing you to have just one vacuum box body and to choose the desired base configuration.

Vacuum Generation Capacity

The surfaces under inspection can be very heterogeneous depending on the application requiring this type of control. For instance, in the case of roofing or terrace roof leak testing, your surface will be smooth and regular with very little deformation, whereas in the case of a petrochemical industry storage tank, you may encounter irregular, granular, or even abrasive surfaces with significant excess thickness (especially in the case of fillet welds).

The success of the leak test depends directly on the foam’s ability to conform to the shape of the inspection surface; otherwise, a vacuum cannot be created.

To perfectly address these challenges, we have conducted extensive development work on our foams regarding their shape, material, manufacturing method, and adhesion to ensure unmatched versatility and durability in the market.

Depression Modes of our bubble leak test equipment

Our different suction box are equipped with a hybrid vacuum system that operates either by venturi effect when coupled with a compressor (1) or by a vacuum pump or vacuum pump box (2).

Regardless of the mode of operation, our vacuum box have a rapid vacuum release system to allow quick detachment and repositioning of the box for successive leak testing.

Vacuum Control and Regulation

To verify that the conditions for vacuum leak testing are suitable and thus ensure defect detectability, it is necessary to ensure that the vacuum is below a certain value (depending on the control standard to which you are subject).

For this purpose, the vacuum box are equipped with a vacuum gauge and a manual regulation system to adjust the maximum vacuum. This adjustment capability will be very useful when testing on thin surfaces where excessive vacuum could deform the surface itself.

Associated Standards for Leak Testing LT

NF EN 1593 Non-destructive testing – Leak testing – Bubble test

NF EN 1779 Non-destructive testing – Leak testing – Criteria for method and technique selection

NF EN 13184 Non-destructive testing – Leak testing – Pressure change method

API 650 – Vacuum box test pressure procedure

Example of leak testing inspection procedure: API 650 – vacuum box testing tank bottom

Main requirements of the API 650 for vacuum box inspection :

- The temperature of the elements to be inspected must be between 4° and 52°C (39.2° and 125.6°F).

- The soap solution must be applied to the surface being inspected until it is thoroughly wetted.

- The pressure conditions inside the bubble leak test equipment should be between 3 and 5 psi, or 21 to 35 kPa.

- The vacuum must be maintained at this level for at least 5 seconds.

- There must be an overlap of the inspected areas of at least 2 inches or 50mm when the vacuum box weld testing equipment is moved.

- …