Magnetix MGN2.5 Battery-Powered Magnetic Particle Inspection Kit

Photos non contractuelles

Looking for the perfect balance between ergonomics, performance, and reliability for your NDT magnetic particle inspections? Look no further: our MGN2.5 MPI kit perfectly meets your needs.

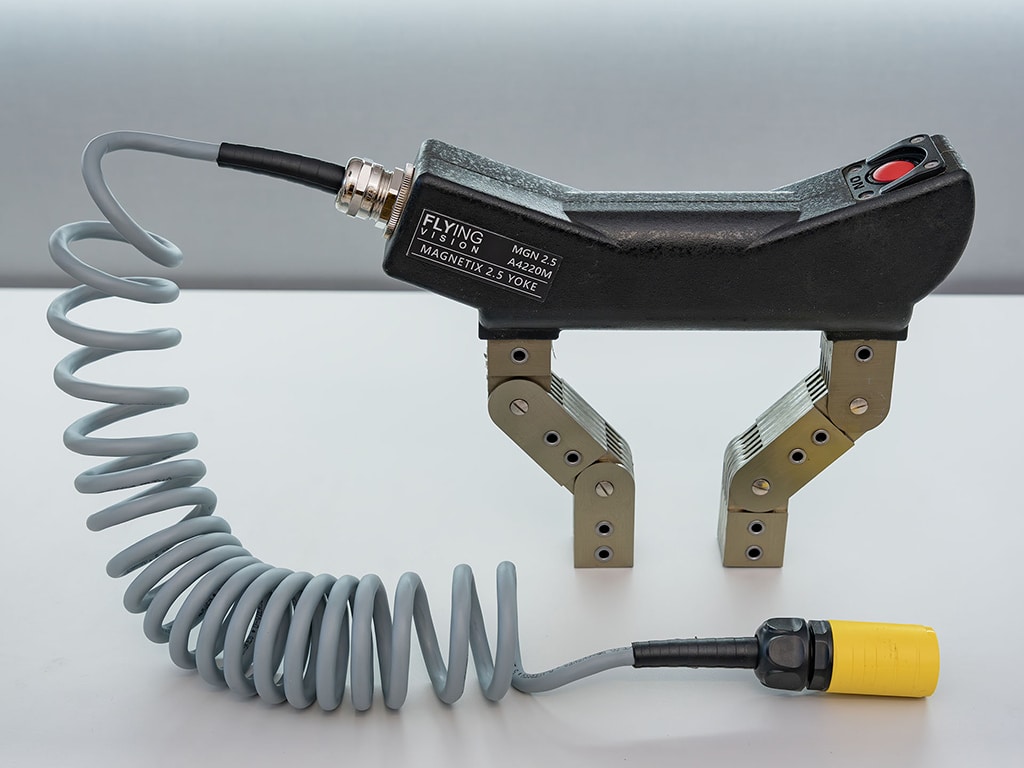

Our battery-operated portable magnetic particle inspection kit, Magnetix MGN2.5, is the natural evolution of our previous MPI battery kit, the MGN2. This development was specifically carried out to meet the most demanding standards and applications. While maintaining its ultra-portable nature and ergonomics that have contributed greatly to its success, the MGN2.5 offers, among other things, a new magnetic yoke that achieves the best performance in this market segment.

PRESENTATION ET APPLICATIONS

If you’re looking for a portable magnetic particle inspection equipment suitable for controls in various situations, the Magnetix MGN2.5 is the ideal choice. Whether for on-site inspections in confined spaces, at height on ropes, or in workshops where a mobile and efficient solution is crucial to optimize performance, our portable magnetic particle inspection kit, Magnetix MGN2.5, meets all these requirements.

Our portable MPI inspection kit, Magnetix MGN2.5, combines the strengths that made our previous version, Magnetix MGN2.0, successful while offering exceptional performance, especially with its new magnetic yoke. This kit is now an essential reference for the most rigorous magnetic particle inspections.

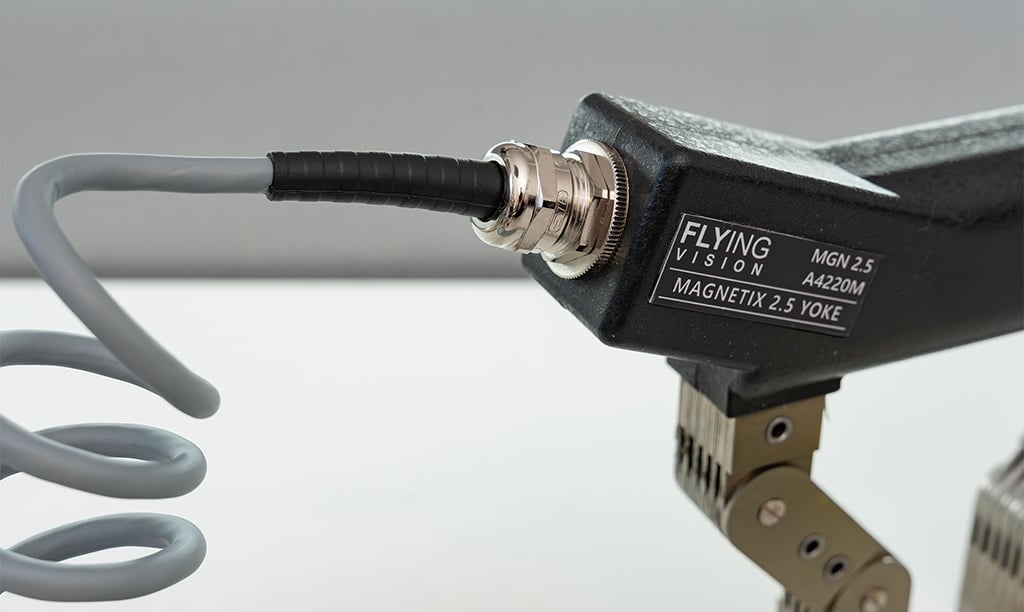

Our ndt mpi kit maintains its excellence in terms of ergonomics, lightness, and reliability. The connections between connectors, cables, and components of the kit have been further improved for increased resistance to snagging during use.

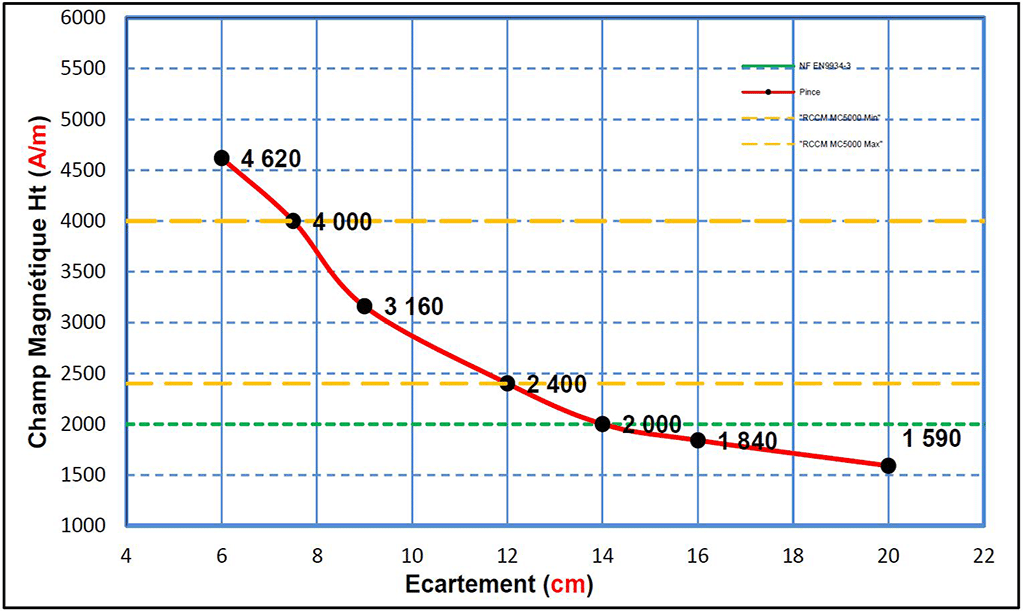

The new AC electromagnetic yoke stands out with an extended duty cycle, exceptional robustness and reliability, and tangential magnetic field values that position it as a leader in the market for portable magnetic control systems.

ADVANTAGES

Quality and Reliability

Our mpi battery kit is manufactured using high-quality materials such as aluminum alloy, stainless steel, and polyurethane for enhanced durability and resistance to chemicals and abrasion

–

Special attention has been paid to the protection of the cable gland connections to maximize cable life and to limit the impact of snags on the field

Ergonomics and Lightness

Reinforced ultra-portable magnetic particle inspection system, designed to be compact, light, and ergonomic, ideal for use in challenging terrain

–

Adjustable belt system adaptable to all body shapes

–

Lateral placement of components at hip level for full operator mobility

–

Quick belt closure thanks to a firefighter-type quick-release system

–

Magnetic yoke housing with an ultra-simple magnetic locking system

–

Secure battery slot on a rail for easy one-handed change

Safety

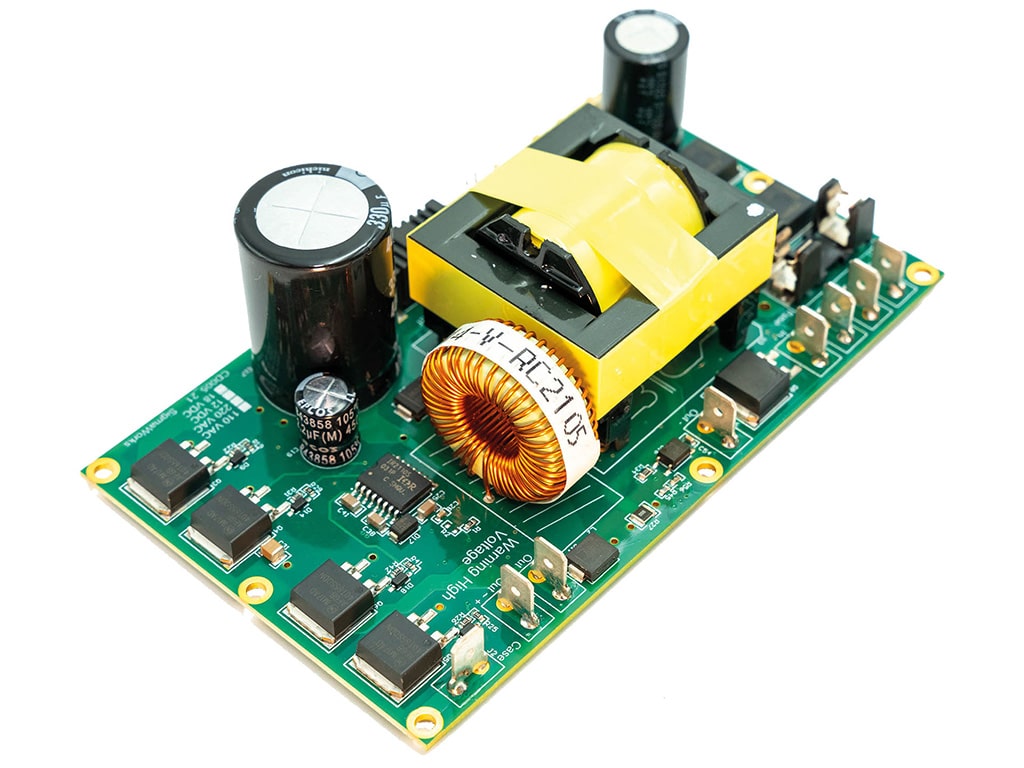

The electronic board of our MPI power driver has been specifically designed for our magnetic particle inspection system, with a particular focus on increasing overall safety. With the integration of a microcontroller, it is capable of interpreting data from various sensors to monitor key parameters such as temperature, current, and voltage. It also informs the user of any potential issues through a human-machine interface and activates safety measures when necessary. This technological innovation positions us to offer you the most advanced and high-performing portable AC NDT MPI system on the market.

FUNCTIONALITIES

User interface

The power driver of our mag yoke battery kit, Magnetix, incorporates a microcontroller connected to an LED system on the activation button. This feature communicates the system’s status and alerts the user to any potential problems.

There are two types of signals on our Magnetix power driver:

- A modulation of light, which conveys information about the system’s status, such as initialization, ignition, pre-standby, or duty cycle.

- Light flashing, indicating error messages, such as low battery, too high temperature, or abnormal current…

Duty cycle management

To enable continuous magnetic particle inspections and maximize the usage time of your system, we have designed our electromagnetic yoke to ensure a usage factor, or duty cycle, of 50%.

The duty cycle defines the maximum recommended usage time before the electromagnet yoke can no longer effectively dissipate the heat it generates, and consequently, starts to overheat.

This factor is directly related to the dimensions of the metal legs / poles and therefore its ability to dissipate heat. The pole section of our mag yoke is 25 x 25 mm, or 6.25 cm².

Quick Connection of Peripherals

To maximize the reliability of our mpi system, we have carefully designed the connections between peripherals. These connections are made using reinforced quick connectors, paired with polyurethane (PU) cables that are resistant to hydrocarbons and lacerations. At the cable glands, the cables are further reinforced by an injected polyurethane strain relief molding, providing additional protection.

Mag yoke – Activation

Mag yoke – Pole adjustment

The pole spacing of our Magnetix MGN2.5 magnetic particle inspection yoke is adjustable from 0 to 240 mm. This mpi yoke is distinguished by an exceptional power-to-weight ratio. It offers, in addition to a remarkable tangential magnetic field level (2000 A/m at a spacing of 140 mm, measured center to center), a lifting force well above the specification >4.5kg of the ISO 9934-3 standard.

TECHNICAL CHARACTERISTICS

| Technical characteristics | Details |

|---|---|

| Working Voltage | 220V AC 50HZ |

| Pull Force / Lifting Capacity | > 4.5 Kg |

| Electromagnet Mass | 2.6 Kg |

| Pole Section | 25 x 25 mm (6,25 cm²) |

| Duty Cycle | 50% |

| Protection Rating IP | IP 54 |

| Battery Type | Portable-type Li-ion |

| Battery Capacity | 4 Ah |

| Battery Life | Up to 2 hours with a 50% duty cycle (space for 4 batteries in the kit, therefore up to 8 hours) |

| Total Kit Weight (excluding case) | 5.7 Kg |

| Total Kit Weight (including case) | 12 Kg |

Fichiers téléchargeables :

-

Présentation